Share

IoT devices ship with more capabilities and far more complexity. That brings embedded engineering teams new failure modes, unexpected field behavior, and constant pressure to deliver reliable devices at scale. Effective IoT device monitoring equips them to detect crashes while tracking resource usage and connectivity patterns. With more visibility, teams can fix issues long before they become customer-impacting outages.

In this piece, we’ll break down:

- What IoT device monitoring is

- Why it matters for embedded teams

- The challenges you should anticipate in improving your device monitoring

- The capabilities that distinguish a strong monitoring solution.

Is your team scaling from prototypes to your first real fleet? Are you trying to wrangle an already-large deployment? This guide provides the foundational perspective you need to build a monitoring strategy that actually works.

What Is IoT Device Monitoring?

IoT device monitoring is the practice of collecting, storing, and analyzing telemetry from devices deployed in the field. For embedded teams, that telemetry is usually firmware-level data: crash dumps (or core dumps), reboot reasons, connectivity state transitions, memory usage, performance metrics, and any custom device behavior signals.

If you’re coming from cloud or mobile development, this can feel like trying to build observability with one hand tied behind your back. Embedded devices have limited RAM and flash memory, intermittent connectivity, constrained power budgets, and sometimes connect via extremely low-bandwidth networks. Given those limitations, it’s important that observability be designed into the firmware from the beginning, with careful attention paid to data formats, buffering strategies, and upload timing.

Proper monitoring shows you how devices are actually behaving in the field. Without it, you’re relying on customer reports, intuition, and luck.

Why Does Monitoring IoT Devices Matter?

Connected Devices Are Only Getting More Complex

The lines between hardware and software are blurring, and embedded systems are always growing more complex. A device that once collected a sensor reading and pushed it over a universal asynchronous receiver/transmitter (UART) may now support multiple wireless stacks, over-the-air (OTA) updates, secure boot, local machine learning (ML) inference, application-level logic, backwards-compatible interfaces, and more.

As the stack grows, so does the variety of things that can go wrong. That includes subtle timing issues, low-memory conditions, radio instability, power-management edge cases, and regressions introduced during refactoring.

Monitoring IoT devices provides real-world data that helps embedded teams navigate that complexity. Effective monitoring helps ensure that, when something fails in the field, embedded teams learn what happened from the device itself rather than from a user.

Inadequate Device Monitoring is Costly

IoT device failures are expensive to users and device makers alike. The cost of a single hour of downtime can range from $40,000 (consumer goods) to more than $2 million (automotive manufacturing), according to a 2024 study by Siemens.

Without precise diagnostic data, device repair and debugging cycles drag on, slowed down by:

- High support load

- Costly site visits and returns

- Difficulty reproducing issues

- Slow or risky OTA rollouts

- And even product recalls.

There’s also a steep opportunity cost. When engineering teams are consumed with solving ambiguous customer support requests, they spend less time building new features and improving products.

The sum of all those slowdowns is declining customer trust.

With visibility into crashes, resource usage trends, and connectivity patterns, you get early warning signals and a much shorter path from issue to root cause to fix.

Challenges Embedded Teams Face When Monitoring IoT Devices Themselves

At some point, engineering teams who make and manage IoT devices face a choice: whether to build or buy a system for monitoring those devices. Those who build in-house observability need to account for some unavoidable challenges:

Scaling from Prototypes to Fleets

During prototyping, you might rely on printf logging, JTAG/SWD debugging interfaces, or vendor-provided integrated development environment (IDE) debugging tools. These are all useful for early development, but they don’t scale to thousands of deployed devices.

A scalable monitoring solution must shift debugging from hands-on hardware probing to cloud-aggregated, device-reported telemetry. For reMarkable, maker of paper-feel tablets, adopting Memfault’s platform for monitoring IoT devices was key to making the leap from startup to established brand.

Limited On-Device Storage and Connectivity

Even a small circular buffer can fill up quickly if logs are verbose. And if your devices rely on intermittent Wi-Fi, low-power cellular, or satellite-based connectivity, you may get only a few kilobytes per day.

Monitoring systems built for embedded must work with (not against) these limitations.

Firmware Fragmentation

As products evolve, and the number of components and vendors proliferates, your fleet may end up depending on equipment with many different firmware versions, hardware revisions, bootloaders, and vendor SDK revision processes. This fragmentation makes correlation tricky. You need monitoring tools that aggregate by version and track behavior over time.

Data Privacy and Security

Telemetry must be encrypted, authenticated, and transmitted securely. Embedded teams also need a way to filter or anonymize data depending on compliance requirements, especially in healthcare, energy, and industrial contexts.

What to Consider in Third-Party Tools for Monitoring IoT Devices

Given the ongoing issues that come with building and maintaining an in-house solution, it’s common for teams to assess solutions from vendors. Here’s what they should seek in a third-party system:

Quality and Quantity of Firmware Signals

Some telemetry signals provide disproportionately high value for embedded teams:

- Crashes, faults, core dumps, and reboots: This is the “X-ray vision” of firmware debugging. Capturing register values, stack traces, breadcrumbs, and relevant memory regions lets you diagnose a fault even when you can’t reproduce it locally. Without this, you’re chasing ghosts.Reboots are valuable events, too. Tracking them gives teams insight into whether devices are resetting in the field because of simple firmware bugs, environmental factors, or more serious communication issues.

- Resource usage metrics: Memory fragmentation, high heap usage, CPU spikes, flash wear, and other indicators often reveal slow-burn issues that degrade device stability. Tracking these metrics over time is essential for spotting regressions early.

- Connectivity and uptime data: Connectivity is often the biggest source of field instability. Data on signal strength, reconnect attempts, disconnections, connection durations, and firmware version distribution help you determine whether issues are device-related, network-related, or user-environment-related.

Real-World Constraints on Data Collection

Embedded devices can’t continuously stream logs the way server applications can. The monitoring strategy has to respect real-world constraints:

- Offline caching: Devices should store telemetry locally when disconnected.

- Data prioritization: Crashes outrank metrics; metrics outrank verbose logs.

- Efficient encoding: Since bandwidth is precious, telemetry must be compact.

- Non-intrusiveness: Monitoring must not meaningfully degrade device performance.

Well-designed observability systems allow you to collect meaningful data while keeping RAM, flash, and power budgets intact.

Benefits of Effective Monitoring of IoT Devices for Embedded Teams

Faster Debugging and Root-Cause Analysis

When a device crashes, you get actionable context: the faulting instruction, the stack trace, and the breadcrumbs leading to the problem. This turns debugging into a data-driven process instead of guesswork.

Consistent OTA Updates

Monitoring and OTA form a feedback loop. You roll out a firmware version, watch telemetry for regressions, pause or roll back if anything looks off, and proceed once you’re confident the update is stable.

Cross-Functional Collaboration

Observability unlocks shared understanding across product, support, operations, and engineering. Everyone is looking at the same data instead of debating what “probably” happened.

Key Capabilities to Look for in an IoT Device Monitoring Platform

End-to-End Visibility

Good platforms collect all the signals that matter: crashes, metrics, logs, connectivity data, and reboot reasons. They also present that data consistently across environments, firmware versions, and device types.

Fleet-Level Insights

You want to see trends, not just anomalies. Device fleets behave differently at scale, and fleet views reveal patterns that would be invisible on single units.

Root-Cause Debugging

Automated symbolication, deduplication, correlated traces, and annotated crash groups make it possible to diagnose issues without manually digging through raw dumps.

Integration with OTA and CI/CD pipeline

By linking telemetry to releases, embedded teams get a real closed-loop system: deploy, observe, fix, repeat. Teams that connect firmware signals with OTA rollout phases can make faster, better decisions on how to address issues before they affect bigger parts of their fleet.

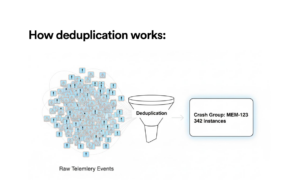

Deduplication

When multiple devices transmit the same data or a single device transmits it repeatedly, the duplication consumes bandwidth and battery power. Deduplication reduces data noise for teams.

Broad Agnosticism

Look for monitoring platforms that do not limit your chip, connection, or development kit choices. An agnostic platform lets teams switch hardware or connectivity without re-architecting their entire monitoring approach.

Flexible Cohort Creation

Grouping devices into cohorts streamlines device monitoring and management by allowing for staged rollouts, smarter beta testing, and more organized multi-device management. Monitoring platforms should let you define cohorts whenever and however you choose.

Industry Use Cases for IoT Device Monitoring

Across industries, the specifics may change, but the underlying challenge persists: operating connected devices in unpredictable environments where failures are costly, visibility is limited, and users expect seamless performance. Effective monitoring gives embedded teams the data they need to understand how devices behave in the field, shorten debugging cycles, and prevent minor issues from turning into large-scale incidents, whether their IoT products operate in a user’s kitchen or on a factory floor.

Consumer electronics

IoT wearables, smart-home devices, and audio products have become a part of everyday life for millions of people. When they fail, workdays get more difficult, and cycling miles go uncounted.

Embedded engineering teams at reMarkable consolidated their disparate OTA update management and observability tools into a single platform with Memfault. The result: three-times-faster releases and 40% fewer hotfixes.

“If we hadn’t implemented Memfault, we might not have had the bandwidth to build our AI features,” said Nico Cormier, reMarkable chief technology officer.

Home automation

In millions of homes, IoT automation tools literally keep the lights on, the ceiling fans running, and the shades drawn. To do that, devices have to integrate with networks, hardware, and software from a diverse collection of vendors.

Bond Home, maker of the popular Bond Bridge home automation controller, reduced firmware fix times from hours to minutes by integrating Memfault crash data collection into a recent firmware update

“Our number one goal with Memfault is to have really good crash analytics,” said Chris Merck, Bond Home’s vice president of engineering.

Environmental quality, industrial, healthcare, energy and utilities

Effective IoT device monitoring is essential in a wide range of industries. Air quality and weather prediction devices often live in harsh environments with unstable connectivity. In factories, monitoring ensures equipment stability and predictability, and enables remote failure diagnosis.

Medical and wellness devices demand reliability, traceability, and secure telemetry, all of which robust monitoring delivers. Smart meters, EV chargers, and grid sensors often operate with sparse connectivity but high uptime requirements. Monitoring ensures warnings before outages cascade.

How Memfault Makes Monitoring IoT Devices Simpler for Embedded Teams

Memfault is the first cloud service tailored to the management of smart devices. It’s designed by people who’ve built and shipped embedded devices themselves, so they know engineers need: a tiny SDK, workflows that match embedded engineering realities, and tools that feel like extensions of the firmware development process.

- With Memfault’s observability tools, teams get:

- Rich device telemetry with reduced overhead

- Fleet-level dashboards and alerts and

- Seamless OTA updates and CI/CD pipeline integration

Building and maintaining a connected device is no longer just a matter of writing reliable firmware. It also requires an understanding of how that firmware behaves in the real world, across thousands or millions of devices. That’s what IoT device monitoring provides: proactive visibility, faster debugging, safer releases, and confidence that your fleet is operating as intended.

For embedded teams, a strong monitoring strategy means capturing high-value telemetry signals, navigating device constraints, and choosing a platform that supports fleet-level insight and deep root-cause analysis. Solutions like Memfault bring these capabilities together in a way that’s purpose-built for firmware engineers, enabling a more stable product today and a more scalable IoT operation tomorrow.

If you’re preparing your first deployment or managing a complex fleet, now is the time to invest in the tooling and processes that make device monitoring a core part of your engineering workflow.

Learn more about how IoT monitoring issues affect 200 U.S. IoT decision-makers in The IoT Visibility Gap, a study commissioned by Memfault.

Citations

- The True Cost of Downtime 2024, Siemens AG

- “How IoT Is Playing A Key Role In Production Uptime”, By Anil Bhaskar, Forbes

- “Top 12 IoT applications and examples in business”, By Mary K. Pratt, TechTarget

- “IoT Smart Sensors Monitor School Indoor Air Quality to Keep Students Safe”, by David Antar, Campus Safety magazine

- “The Internet of Things: Impact and Implications for Health Care Delivery”, By Jaimon T. Kelly, Katrina L. Campbell, Enying Gong and Paul Scuffham, Journal of Medical Internet Research

- Grid Modernization and the Smart Grid, U.S. Department of Energy

- “Monitor performance of every deployed device”, Memfault Product Page

- “How To Test Your IoT Product Before Launch”, Jesse Dukes, Memfault

- “OTA for IoT: What It Is, How It Works, and Why It Matters”, Siara Singleton, Memfault

- “The #1 Thing to Consider When Building an In-House IoT Observability System”, Ryan Case, Memfault

- Webinar: From Startup to Global Brand: Scaling Engineering at reMarkable

- “reMarkable keeps millions of devices updated and highly reliable with Memfault”, Memfault Customer Case Study