Share

What happens when a wearable IoT brand can’t see what’s going wrong in the field, and what changes when it finally can?

The answer reveals something important about how wearable products succeed or fail. Reliability is the currency of trust in wearables. These devices are not tucked away on shelves. They move through the world with users, track vital information, and carry the weight of real expectations. When something goes wrong, the cost is clear.

Gabb, the kid-safe technology company, learned this firsthand. Their team built a purpose-built watch to keep children safe and give parents peace of mind. But without visibility into how their watched performed after shipping, they ran into obstacles that limited them from reaching their full potential.

The Gabb Watch 3e demonstrated how observability can shift outcomes, not only for engineering teams but for the entire bottom line.

In the world of wearable IoT, reliability is the difference between a product that’s returned and one that’s recommended. When a child’s safety device, like the Gabb Watch 3e, encounters issues, parents could lose confidence, and the brand’s reputation could suffer. But Gabb was determined not to let that happen. Reliability quickly became a mission-critical metric for their team and, ultimately, a significant sales driver.

If any wearable team is looking for hope that they can turn a device’s fate around after launch, Gabb sets the standard. They now boast a reliable, highly rated product trusted by parents and loved by their children. Their team showed what’s possible when dedication meets the proper set of tools.

We’ll share how they did it and what wearable IoT brands can learn from their observability journey.

When Wearables Go Quiet: Why IoT Monitoring is Harder Than It Should Be

For most connected products, the launch is not the finish line. It marks the start of a new phase that demands visibility into how devices behave in the field. This challenge is especially acute for wearable IoT products. These devices must perform consistently under various conditions and environments, but engineering teams often struggle to monitor their performance once they ship.

Common barriers include:

- Firmware behavior is tricky to observe without shipping devices back and forth for diagnostics.

- Debugging typically begins only after customers report problems, delaying issue resolution.

- Returning devices for analysis can take weeks, stretching timelines and consuming resources.

- Issues often disappear before investigation, especially if users reset devices or problems occur intermittently.

This is the landscape Gabb was navigating when they encountered persistent battery issues in the Gabb Watch 3e. Despite strong tooling for application and backend monitoring, their team couldn’t observe firmware behavior across the field. Without that, even basic troubleshooting became unpredictable and slow.

Chad Baucom, Director of Product for Wearables at Gabb, shared, “We would spend months sending devices back and forth between our headquarters, manufacturers, and battery supplier, only to hear, ‘We can’t find a problem.’ Meanwhile, more and more customers were reporting the same issue.”

This kind of uncertainty takes a toll on teams working to deliver reliable, user-centered products. The harder it is to see what’s happening on real devices, the harder it becomes to build the experience customers expect. Gabb knew they needed a better way forward— one that offered clarity, speed, and confidence at scale.

Gaining Clarity at Scale: Gabb’s Path to Exceptional Wearable IoT Monitoring

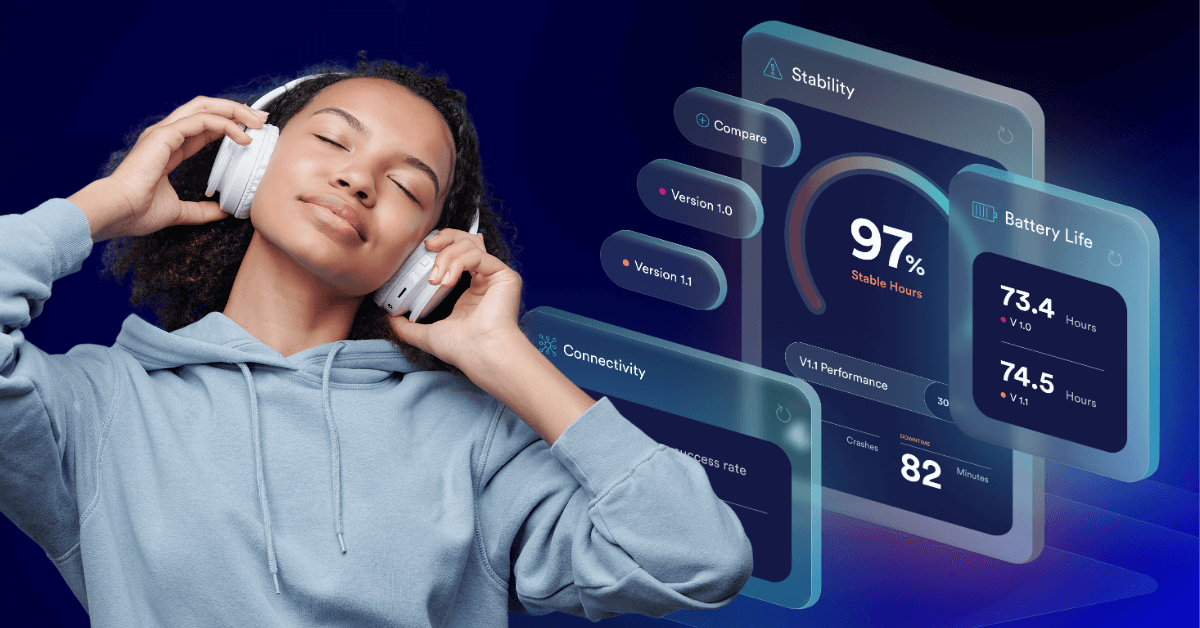

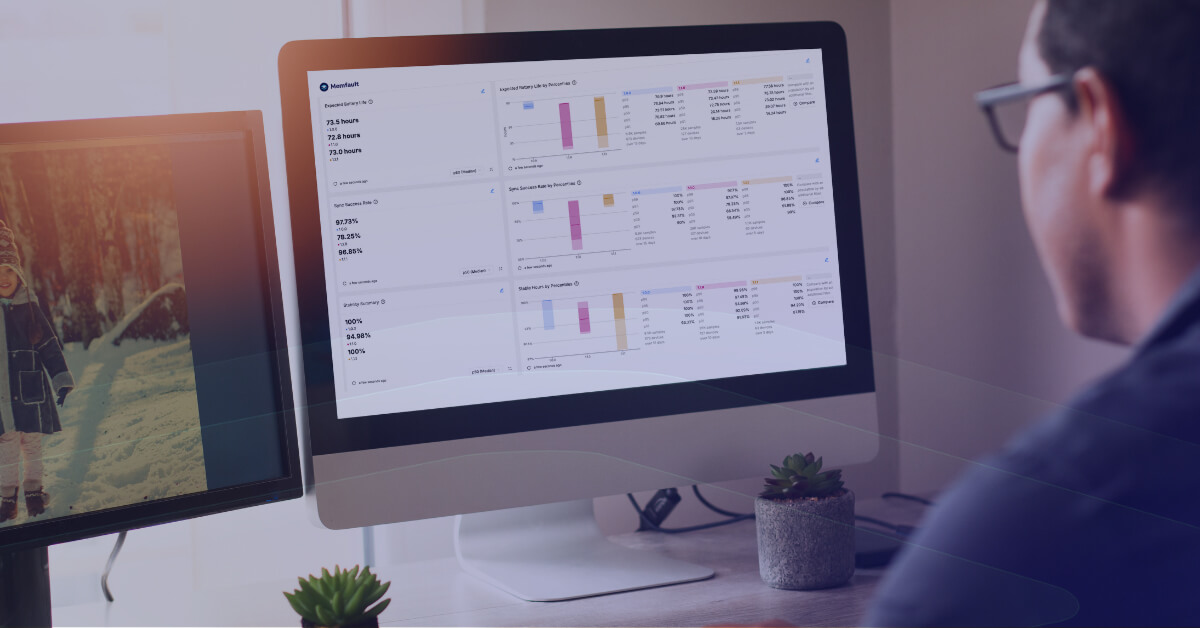

When Gabb integrated Memfault into the Watch 3e, they finally gained the visibility their team had been working without. Engineers could trace real-world battery behavior across thousands of devices and no longer relied on scattered anecdotes or RMA’d devices to make sense of what went wrong.

Now, Gabb’s engineering team had the tools to uncover a firmware setting that was shutting devices off too early. Once identified, they adjusted the configuration and deployed a fix using over-the-air updates, ensuring fast resolution across the fleet.

“Battery life went from lasting only part of the day to 28 hours on average. That was a game changer for parents and kids,”— Chad Baucom, Director of Product for Wearables at Gabb

What started as a targeted fix became a new way of working. Gabb began resolving issues before customers were affected, shortening iteration cycles, and aligning product decisions with real usage data.

Gabb’s story reflects a broader shift. Catching bugs is nice, but observability is about building a feedback loop that factors in field performance. Memfault made it possible to monitor fleet-wide health, spot regressions early, and collaborate across teams with shared context.

Instead of waiting for problems to surface through returns or reviews, engineering teams can see issues in real time and solve them while the devices stay with users.

Want to hear directly from the Gabb team? Join us live for an upcoming Coredump session, where Gabb’s product leaders will share what it really takes to build reliable, kid-safe tech— and how observability plays a central role.

What Gabb Gained with Observability

Real-time insight into device behavior changes how teams operate. For Gabb, it led to noticeable improvements in product performance and business outcomes:

- Sales grew by 20-30%

- Battery life extended to 28 hours on average

- Amazon rating increased from 2.9 to 4.2 stars

- Debugging time dropped from months to minutes

Alongside these wins, Gabb also saw a drop in customer support volume as issues were resolved earlier in the process. Even more, their engineering team shifted focus toward feature development, no longer bogged down by long debugging cycles.

What Wearable IoT Teams Can Learn From Gabb’s Transformation

Gabb’s success was the result of deliberate changes. Their team identified a problem affecting real families and acted quickly with the right tools. The result was a product parents could trust and a business with serious momentum.

For other wearable IoT teams, the path forward may look different in detail, but the principles hold. Observability in the field enables faster decision-making, sharper prioritization, and stronger alignment across engineering and product. What begins as a technical capability often becomes a shift in how teams work and how products evolve over time.

Fix wearable IoT device faults fast before your customers even have time to notice.

Memfault supports that shift by turning fleet-wide device behavior into meaningful, usable insight. The platform allows teams to detect issues, understand their impact, and respond quickly and confidently. Every improvement begins with knowing what’s happening and having the means to act on it.

The companies shaping the future of embedded systems will be the ones that treat reliability as a continuous practice. With the right approach, every release becomes an opportunity to strengthen what’s already in the field.

Read the full case study to see how Gabb made it happen, or book a demo with our team to explore how observability can elevate your development process.