Share

Every consumer IoT device company dreams of launching a near-perfect product just in time for the holiday push. The reality is: shipping a device is very scary. It’s the moment when timing, polish, and performance converge to either make or miss the year’s most valuable revenue window. The best-in-business brands have made the moment look effortless— it’s not. Our team members have supported launches with brands like Whoop and Fitbit and can tell you: it takes a lot of behind-the-scenes work to pull it off.

The engineering teams at these companies all have something in common: they prioritize processes, invest early in infrastructure, and build in a way that makes last-minute surprises less likely and post-launch pivots more manageable. We’ve seen these patterns in action and want to share them with you.

What follows are the key considerations for getting a product into customers’ hands by mid-December. Some are foundational, and others are hard-won lessons you will not find in the standard launch checklist.

Call it a blueprint. Call it a survival guide. Just don’t launch without it.

The Top Mistakes That Torpedo Holiday Launches

The pressure of launching a product in time for the holidays is real, and it’s easy to make costly mistakes. In a process as complex as embedded device development, cutting corners and procrastinating will always end the same way: painfully.

Learn from these common pitfalls and save your team from unnecessary stresses and delays:

- Delaying OTA integration: Waiting too long to integrate over-the-air updates (OTA) means your testers may end up working with outdated firmware, leading to inaccurate bug reports and missed opportunities for improvements. Collecting bug reports on old versions = burned DVT time. Procrastinating on OTA just wastes time and creates a ripple effect of problems later on.

- Rushing through the PVT Phase: Rushing through Product Validation Testing (PVT) without locking the firmware or addressing manufacturing issues risks leaving defects and delays that could’ve been avoided. Get the firmware locked before scaling production to prevent complications.

- Ignoring Manufacturing Scalability: Failing to optimize your production line is a mistake. If you don’t fine-tune every station for speed and quality, bottlenecks will creep up, throwing off your entire timeline. Efficiency in this phase is non-negotiable if you want to avoid delays.

- Lack of Pre-Launch Monitoring: Pre-launch is the opportunity to catch those final bugs and improve stability before your product reaches customers. This is also when structured beta or early user testing becomes critical, surfacing real-world issues that internal teams often miss. Without monitoring and external feedback during this phase, you’re rolling the dice with a product that hasn’t been thoroughly tested in real-world conditions.

These are real-world mistakes we’ve seen teams make when the pressure is on and the calendar’s unforgiving. It’s always better to learn from someone else’s misstep than to explain to your execs why the big holiday push is running late. To avoid that conversation entirely, you need a clear roadmap that starts months earlier and leaves nothing to chance.

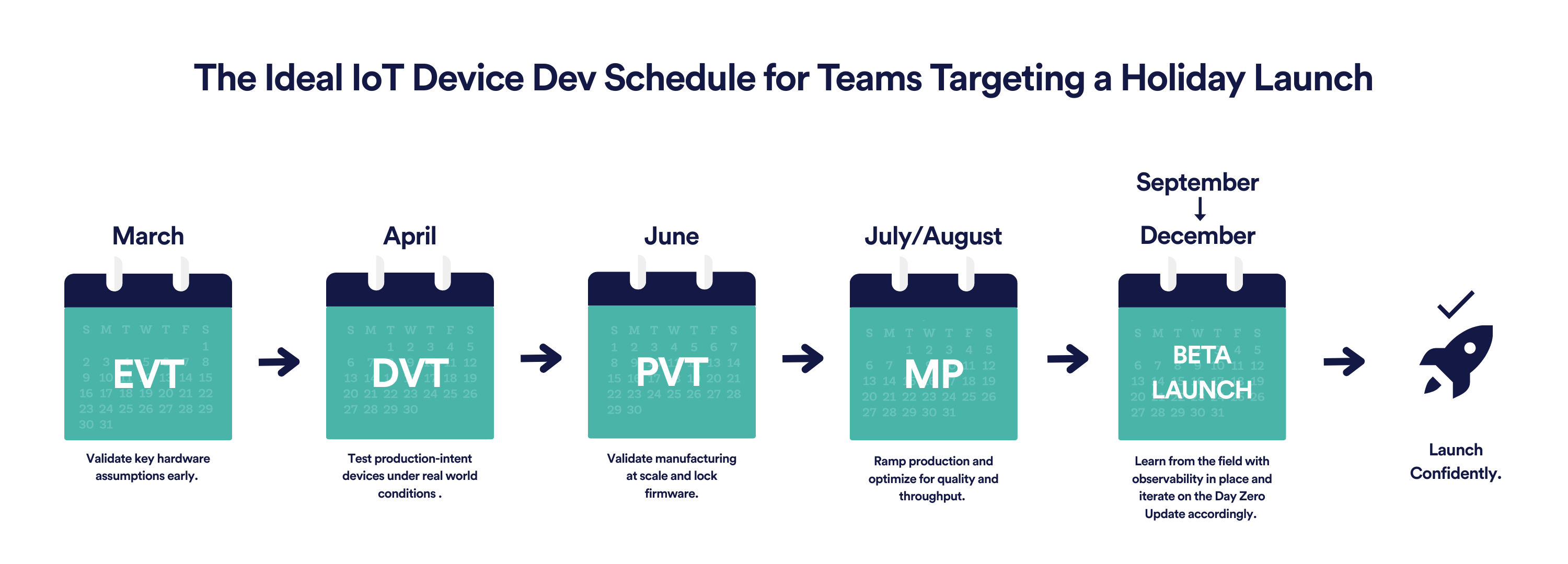

The Stage-by-Stage Schedule Behind Every Great Holiday Launch

The embedded teams that deliver the right product on time work backward from their target shelf date and understand which phase their hardware and firmware need to be in and by when.

A good rule of thumb: If you’re aiming to hit shelves for the holidays, your product needs to be shipping by September, with early October as the absolute last fallback.

Why September?

- Retailers place holiday orders in October, so your product needs to be proven and ready before then.

- Manufacturing takes time. You need a buffer to ramp production, identify yield issues, and stabilize your assembly line before volume peaks.

- You can’t fix what you don’t observe. Mid-Q4 launches leave no time to react to final-stage findings, increasing the risk of missed defects and untested updates during the holiday push.

iPhones ship every September for a reason. And it’s no coincidence that the Fitbit Charge 6 launched in September 2023 and the GoPro HERO13 Black was released in September 2024. Attempting to launch an initial product too close to December will dramatically increase the risk of late-stage failures and unhappy users.

Below are the critical checkpoints for any team targeting a Q4 launch, including what each phase entails and why timing matters:

Checkpoint #1: EVT completed by March

Engineering Validation Testing (EVT) is the first time your prototype looks and behaves like the real product. In EVT, you validate key hardware assumptions, such as battery life, component performance, and mechanical fit. Let’s say battery life assumptions fail or interoperability bugs occur (and they usually do), waiting too long cuts into the time you need to resolve them before moving on to the next stage.

Checkpoint #2: DVT underway by April

If you’re still in DVT by May or June, you’re off schedule. Design Validation Testing (DVT) is the turning point when the product is in hand, built with production-intent components, and ready for broader evaluation. More units become available internally, and more stakeholders are using the device. DVT provides a great opportunity for engineering teams to learn about the device’s real-world performance.

Pro Tip: Progressively roll-out from internal users to beta testers: start with employees, then close testers, and scale up slowly to catch issues before the fleet is live.

Checkpoint #3: PVT planned for May/June

Product Validation Testing (PVT) is your first real manufacturing run; this is typically what will ship from the factory. With tooling final and firmware near-locked, you are building at scale to validate throughput, yield, and reliability.

By this point, you are cutting into your buffer for QA, shipping, and any Day Zero Updates.

Checkpoint #4: MP Planned for July/August

Mass Production (MP) is when your device starts to roll off the production line at scale, and optimizing efficiency becomes crucial. Your overall throughput is only as fast as your slowest station. If one part of the line lags, everything downstream pays for it. The focus is on ensuring smooth throughput while maintaining strict quality control, so each unit meets the same high standards as the first.

Following this schedule gives your team the time and space to catch issues early, build confidence in the product, and prepare your organization for a smooth, high-impact launch. It’s the kind of approach that not only sets you up for success in December but also gives your embedded team something rare and valuable in January: time to rest.

Pre-Holiday Launch Checklist: The Final Sprint Before December

It’s September now: MP is in full swing, volume is ramping, and peak exposure is still ahead. Your product is already sitting on warehouse shelves, and some units are already in customers’ hands. Early adopters may even be posting unboxings.

Our team has supported enough holiday launches over the years to spot what the absolute pros do differently. Across that collective experience, one thing is clear: the teams who succeed in December are the ones who use this window to learn what they couldn’t learn internally. This early stretch of real-world usage is a gift, offering the kind of feedback, bugs, and unexpected user behavior that no lab test can replicate. What you learn now will shape the final updates you ship before the season hits full stride.

- Stabilize Your OTA System

Your OTA pipeline needs to be active, tested, and reliable. Don’t put off OTA testing. Devices rolling off the line in MP should receive updates exactly as planned.

Pro tip: Run OTA updates across as many device types, networks, and phone models as possible. What works in your lab might fail in the field if you don’t test for real-world variability.

- Monitor Early Fleet Behavior

Now that real users have your device, it’s time to watch closely. Use observability tools to track crash rates, error patterns, battery anomalies, and connectivity issues in the wild. Early adopters are your signal fire; catching these issues now means avoiding holiday-scale blowups and unnecessary RMAs later.

- Prepare Your Day Zero Update

Continue refining it through the fall and use what you’ve learned to prepare the perfect Day Zero update (the version customers will install when they first power on the device in December).

Ensure that final changes are wrapped with enough buffer to validate and respond. Most teams ship their last firmware by mid-December to reduce risk ahead of the holiday spike.

- Pressure-Test the Backend

The backend systems supporting your product, cloud, update infrastructure, and dashboards need to be battle-ready. Christmas morning is not when you want to discover a capacity limit or a latency spike.

- Coordinate Customer Support Playbooks

With devices already in the field, your support team needs to be ready for the questions and edge cases that come with scale. Align on known issues, prepare troubleshooting flows, and ensure your support tooling can quickly surface logs and fleet-wide trends.

The Systems Behind a Fearless Holiday Launch

No launch process works without feedback from the field. You need tooling that can show you what’s happening in the field, infrastructure that lets you act on what you learn, and confidence that your updates will land cleanly every time.

Teams that succeed in Q4 are those that build observability into their devices from the start. They stabilize OTA pipelines early and treat every firmware update as a chance to improve, not a risk to avoid.

We faced many of the same challenges we’ve talked about here when we launched embedded products like Pebble and Fitbit. We built Memfault because we needed a better way to catch issues early, push updates safely, and keep devices running reliably in the real world. Now it’s what we use to help teams launch on time, scale with confidence, and stay on budget. If you’re launching in December or just tired of flying blind, Memfault can help you ship with less fear.

Your holiday launch deserves fewer surprises.

See how Memfault can help by booking a consultation with our team.